by Chester McKaige

__________________________________________________________

Click the button below to order a copy of our acclaimed book Speed Monarch; the short life of Eric Fernihough and the world’s motorcycle speed record. It is packed with JAP history. For more information about the book please go to one of our earlier posts in the left hand menu panel. PS there is only one BUY button but sometimes three display! Take your pick.

________________________________________________________________________

The post-war motoring enthusiast in Australia was very much like that of his counterpart in England in seeking an affordable means to take up amateur motorsport with whatever came to hand.

Two friends, both working at the Commonwealth Aircraft Corporation near Melbourne, A.M. (Maurice) Wheeler and J. E. (Jack) Gow, decided in their spare time to build a 500cc powered racing car from parts sourced from the ‘scrap bin’ at work. A design was drawn up on the back of an envelope, and work commenced in the summer of 1951.

The design was different to the cars being built in the many garages around Victoria. For a start, the design was to use front-wheel drive with the engine mounted ahead of the front axle. The chassis was of a cruciform construction made of aluminium alloy sheet boxed and riveted together as in aircraft design.

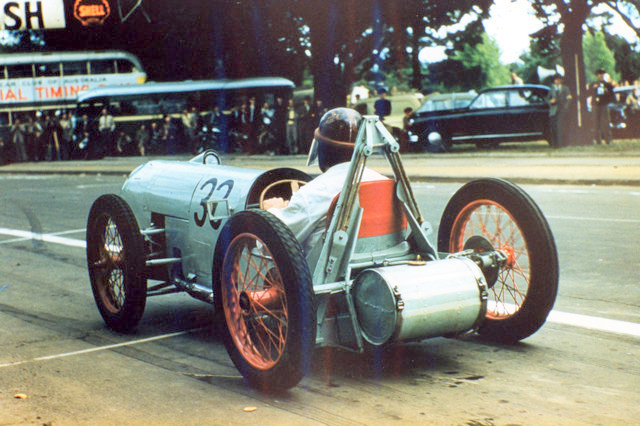

The WGM at the Australian Grand Prix meeting of 1956. Maurie Wheeler is on the left with his arms folded, Jack Gow is on the far right with the clipboard.

The engine used was a Matchless G80 single-cylinder 500cc motorcycle engine which was extensively modified with a compression ratio of 12:1. A large Amal 1-5/32in diameter bore carburettor was used. The engine-driven fuel pump was used to draw fuel from the main tank to a header tank that gravity-feeds the carburettor. The fuel used was Shell ‘A’ methanol. A large SU fuel bowl was later attached to the Amal carburettor.

The front wheels are independently suspended and are mounted on transverse wishbones. The outer ends of the wishbones are connected to full-length fabricated kingpin members with swivelling ends. Suspension is by an assembly of rubber ‘bungee’ cords. Friction dampers are fitted to the upper inboard wishbone pivot shafts.

The drive is straight-through with no differential. From a countershaft fitted with radial ball bearings mounted in the chassis box, the drive is through splined shafts and Holden universals to the front wheels. The final-drive sprocket is mounted on the left-hand side of the countershaft, and the brake disc is on the right-hand side. A Norton gearbox is mounted on top of the chassis box, and the primary chain comes up to it from the engine and the secondary chain then drives down to the final drive sprocket

The rear axle is a beam type and consists of a high-tensile steel tube with the hubs mounted on two radial ball bearings at each end. It is located on the centreline of the chassis at the rear in ‘De Dion’ fashion, with the mounting free to pivot and slide vertically. The outer ends of the axle are located by fore and aft torque members attached to the chassis on their front ends. The suspension uses bungee cord and steel cable mounted on aircraft control pulleys. ‘Hartford’ type dampers are fitted at each side.

Top: The general arrangement of the front end of the WGM in Chester McKaige’s workshop in Tasmania near Launceston

Bottom: the central front disc brake and the drive to the front wheels

The original bungee cord used was an ex-DC3 aircraft undercarriage component that, over time, unravelled itself in what looked like large strands of spaghetti. A new length of cord was obtained from ‘Hanger 9’ in Moorabbin, Melbourne.

Top: the single- sided rear brake

Bottom: the WGM (Wheeler Gow Motors) in its present splendid condition

From the steering arms to the kingpins, divided tie rods with swivel ends are attached to a vertically pivoted sector shaft; aircraft steel cables run back through a series of aircraft control cable pulleys to a drum mounted on the lower end of the steering column with an intermediate pulley system to give a gear reduction.

It is believed the parts used came from the trim-tab controls off a Liberator bomber.

The steering wheel was a later modification, the car originally having a handle-bar! The car is fitted with front and rear disc brakes, and Maurice Wheeler designed these as a result of his experience designing the braking system on the Winjeel trainer aircraft.

(On this subject, note that this was 1951-1952, and Jaguar was the first to feature disc brakes on a race car in 1953).

A single disc ½ “ thick x 10 “ diameter is used at the front, directly mounted to the countershaft axle. The calliper has three 1½” diameter pads on each side of the disc. These are operated hydraulically by three separate pistons of the same diameter using cup seals. They are interconnected together hydraulically. The calliper assembly is mounted on a beam, restrained at each end and free to move laterally to centralise the pads and allow for wear. The material is Ferodo VG 97.

The rear brakes have only one pad on each wheel and are the same dimensions as the front. The calliper is free to move laterally to allow the brakes to centralise.

Two master cylinders ex BMC are fitted. One for the front and one for the rear. They are interconnected by a beam to give proportional braking. In addition to the foot pedal, a hand lever on the left side of the cockpit allows the brakes to be applied by means of a Bowden cable.

Maurie Wheeler writes that the car was originally conceived to provide something different to and more interesting than the general run of rear-engined Cooper type vehicles. The sheet metal and fabrication work was done by J. E. Gow and the mechanical work and machining by A. M. Wheeler. Some 3-4,000 hours of work is a conservative estimate of the time spent on the project.

The car first ran at Rob Roy in 1952. It also ran at Templestowe, Fishermans Bend, Altona and Darley race meetings. The last appearance was at Albert Park in the curtain raiser to the Australian Grand Prix of1956, the Argus Cup, but unfortunately the car broke a crankpin due to driver error. The car was originally driven by Jack Gow, but he retired to get married and Maurice Wheeler later carried-on single-handed for a few years.

After the Australian Grand Prix of 1956, the car was rebuilt to replace the crankpin and cast-iron flywheels, but work commitments got in the way until it was completely overhauled in 1981 and an engine rebuild was completed.

Maurie Wheeler, as already mentioned, climbed the ladder to become a leading draughtsman at the Commonwealth Aircraft Corporation. The author’s father, George McKaige, was also a draughtsman serving under Maurie who went on to become a designer of rockets at Woomera Rocket Range, whilst Jack Gow spent many years across the road in Port Melbourne at General Motors Holden. He was involved in the body design of a large range of Holden cars.

When Maurie eventually retired, my father used to go and visit him and of course watched the rebuild of the WGM. Years passed, and Maurie, a heavy pipe smoker, died. His son was responsible for settling Maurie’s estate. It was proposed that the car would be included in a Shannon’s auction. At that time I was working at Penrite Oil and Lou Russo, owner John Dymond’s mechanic, had begun working on one of John’s Coopers. My father called me and suggested I take a look at the car, simply because it was an intriguing vehicle.

I got hold of Maurie’s son (whose name escapes me) and said I would like to see the car and an acceptable time was made that same day, I recall it being a Sunday.

Before leaving home, I thought I’d take my chequebook just in case.

I looked around the car, asking heaps of questions. I got the impression that it was a bit of a burden hanging around his neck. In the end, I asked him what he wanted for the car, to which, after some thought, he came up with $5,000. I couldn’t write the cheque any quicker than I did.

The next day, during morning tea at Penrites, we were all discussing what we had done at the weekend. I said that I’d bought a 500cc racing car and went on to describe it. Immediately John Dymond and Lou Russo said, we must go and pick it up today and so armed with the Penrite truck, we ventured to Moorabbin, met Maurie’s son and loaded up the car.

Ten days later, Mark Dymond drove it without a muffler around the Penrite factory complex at Bayswater. Lou Russo did some work on it after Mark’s initial drive, and we entered it in a couple of Rob Roy hill climbs and it featured on the poster at Geelong Speed Trials in 1997.

I engaged my brother-in-law to drive it as it was too narrow for me. We had a shake-down run at Calder Park, where the car circulated at 80 mph without a problem. The highlight of my ownership of ‘Bungee’ as it was called was when Jack Gow drove it up Rob Roy, he having not seen the car since 1957.

Today, it sits in my garage amongst my other cars, and later this year, it will have a birthday, with attention being given to its brakes and a new starting device.

What a fascinating car! We would love to see it back out again after its birthday. Thanks for sharing its history

LikeLike